Silt Curtain Type I:

Type I is a light-weight inshore curtain that is ideal for lower energy environments and sheltered deployments with no significant wind or currents. The curtain is designed and manufactured to Gulf Specifications, meaning that it has reinforcing layers and tension bands for additional durability. It is built to last.

Silt Curtain Type II :

is a medium-weight curtain, designed for use in moderate currents. Due to its higher tensile strength, it is suitable for higher velocity water flows in protected waters. The curtain is designed and manufactured to Gulf Specifications, meaning that it has reinforcing layers and tension bands for additional durability. It is built to last.

Type III Silt Curtain :

is a heavy-duty curtain that functions in higher energy environments with currents up to 1.5m/s. It can be deployed in ports, harbours and nearshore conditions with moderate wave exposure up to 1.5m. The curtain is designed and manufactured to Gulf Specifications, meaning that it has reinforcing layers and tension bands for additional durability. It is built to last.

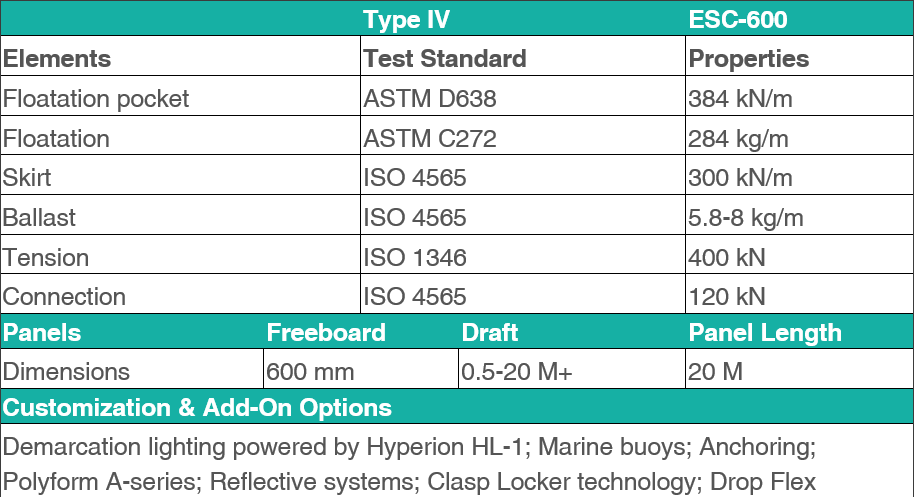

Silt Curtain Type IV (offshore curtain) :

is specifically designed for high-energy environments where currents can be in excess of 1.5m/s and waves in excess of 1.5m. The curtain is designed and manufactured to Gulf Specifications, meaning that it has reinforcing layers and tension bands for additional durability. It is built to last and can be used on multiple projects.

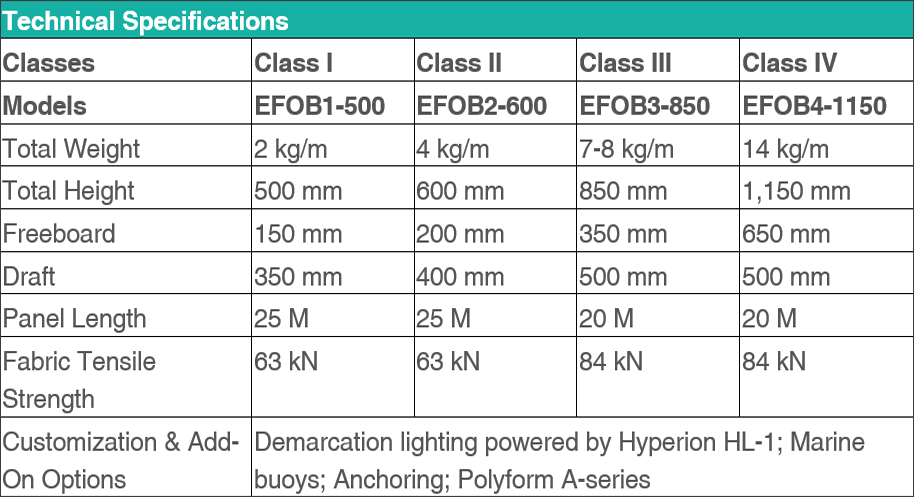

Foam Booms :

Foam Booms are used to block or capture high volumes of surface foam or debris. They are available in four different classes built to withstand low, medium or heavy currents.

The booms are made of UV stabilized PVC membrane fabric in yellow color, but can be produced in different color variations upon request.

To improve identification of the Foam Booms, navigation buoys and Hyperion lanterns can be provided to ensure clear demarcation of the area and an improved night-time lit environment. Further customization is available, as we always aim to meet the needs and requirements of client specific marine environments.

Geosynthetic Containers :

Geosynthetic containers (GSCs) are three-dimensional systems, manufactured from geotextile materials filled with sand. They are not 'sand bags' or 'bulker bags', but require an engineered approach.

GSCs are regarded as innovative, economic and environmentally-friendly systems. They have the added benefit of enhancing marine habitats.

With varying sizes, the containers range from 100 kilograms to over 600 tonnes. The weight provides stability and projects have been designed and constructed in high wave energy coastal areas with waves over 12 meters.

A value-adding solution:

• Stable & effective coastal protection

• Low impact, both environmental & visual

• Environmental enhancements

• Safe for swimmers & beach users

• Better for reputation - no litter on the beach

• Follow-on benefits - tourism, media coverage

Dewatering Containers :

Dewatering Bags are for smaller volume dewatering projects. They are constructed from a robust geotextile fabric to contain sludge and dredged materials from sites.

Unlike the bags, the Dewatering Tubes are perfect for large-scale projects. Due to their high strength and large capacity, they are used extensively in municipal water & waste water treatment projects.

Both in-house engineered and manufactured products provide a more innovative, efficient and cost-effective alternative than the more traditional methods.

Every dewatering project is unique. As such, general guidelines can be described, however each project requires consultation with one of our marine experts to identify the project requirements and design the dewatering process accordingly.

Our Dewatering Bags & Tubes are available in a range of sizes depending on the project